Sidebar

- Home

- Production

- Adamite steel roll and ring

- Alloy indefinite chilled roll and ring(ICDP roll)

- Alloy steel roll

- Graphite steel roll

- Nodular cast iron pearlitic roll and ring

- Nodular cast iron acicular roll and ring

- Enhanced (EN) ICDP roll

- EN HiCr roll

- HSS roll and ring

- Tungsten carbide roll ring

- Forged steel roll for hot rolling mill

- Forged steel roll for cold rolling mill

- Forged roll production flowchart

- News

- About Us

- Contact Us

- Download

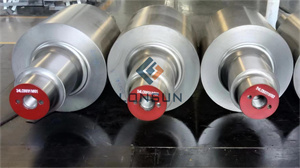

- CNC Roll Lathe

Cemented carbide rolls have good heat conductivity and they are featured by small hardness decrease under high temperature condition, thermal fatigue resistance, good wear resistance and high strength etc., which are not possessed by other materials. The rolls are primarily applied in high speed wire line, Kocks three roll mill, seamless pipe stretch reducing mill, three dimensional rolls for cold-rolled ribbed steel bar, and composite roll for hot-rolled bar screw thread steel etc.

Adamite rolls and rings are performance steel rolls with an optimum combination of wear and fire-crack resistance. This quality has a short range of carbon content, plus varying quantities of Nickel, Chromium and Molybdenum to achieve higher hardness levels. It can be produced either by the Static Monoblock conventional method, or by the horizontal Centrifugal Cast method.

Alloy Indefinite chilled cast iron rolls(called AIC Rolls) are cast high Ni grain rolls with fine deposits of graphite on the surface. AIC rolls also called ICDP(indefinite chilled double poured) rolls. Mainly use to finishing stand of long product mill and HSM.

Pearlitic rolls are composed by nodular graphite and carbides arranged in a pearlitic matrix. It's properties are similar to Indefinite Chill except that the graphite structure is changed from flake to spheroidal forms. Pearlitic rolls will have higher strength than Indefinite Chill. Pearlitic roll can be produced by static casting (Monoblock) or by using the centrifugal cast (CC) Double-pour method.

Acicular Nodular Cast Iron Roll, alloyed with the nickel, manganese and chromium with a bainitic-acicular-martensitic matrix has a higher UTS, hardness and wear resistance is more than the SGP quality. Semi-continuous carbides maintain the wear resistance, while at the same time exhibiting high strength and resistance to fire-cracks.

-

CNC roll lathe

-

Production

-

Nodular Pearlitic Cast Iron Roll (SGP Roll)

-

Duplex High Speed Steel Roll & Ring (HSS ROLL)

-

Tungsten Carbide Rolls

-

Acicular Nodular Cast Iron Roll (SGA Roll)

-

Alloy Indefinite Chilled Cast Iron Rolls(ICDP Rolls)

-

Forged Steel Rolls for Hot Rolling Mills

-

Adamite Steel Roll and Ring

-

En-HiCr cast steel roll/En-HiCr cast iron roll

-

Alloy cast steel roll

-

Graphite steel roll

-

Enhanced ICDP rolls

-

Forged Steel Rolls for Cold Rolling Mills

-

The Forged Roll Production Flowchart

-