Sidebar

- Home

- Production

- Adamite steel roll and ring

- Alloy indefinite chilled roll and ring(ICDP roll)

- Alloy steel roll

- Graphite steel roll

- Nodular cast iron pearlitic roll and ring

- Nodular cast iron acicular roll and ring

- Enhanced (EN) ICDP roll

- EN HiCr roll

- HSS roll and ring

- Tungsten carbide roll ring

- Forged steel roll for hot rolling mill

- Forged steel roll for cold rolling mill

- Forged roll production flowchart

- News

- About Us

- Contact Us

- Download

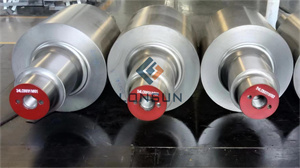

- CNC Roll Lathe

Acicular Nodular Cast Iron Roll, hardness and wear resistance is more than the SGP quality, while at the same time exhibiting high strength and resistance to fire-cracks.

SGP rolls are composed by nodular graphite and carbides arranged in a pearlitic matrix. We called SGP roll or Pearlitic Nodular Cast Iron Roll.

The forged steel rolls for cold mills are widely applied to work rolls, intermediate rolls and back up rolls. The good performance of Lonsun rolls thanks to the high and homogeneous hardness in the work layer with superior wear ability, high toughness and excellence resistance to accident, and the depth of hardness layer may be over 30mm.

The forged steel rolls for hot mills are manufactured by forged steel blanks with special heat treatment is applied to make rolls in satisfactory barrel hardness and hardening depth. The forged rolls for hot mills have good wear-ability, high toughness and excellent biting ability.

The good performance of Lonsun rolls thanks to the high and homogeneous hardness in the work layer with superior wear ability, high toughness and excellence resistance to accident, and the depth of hardness layer may be over 30mm.

-

CNC roll lathe

-

Production

-

Nodular Pearlitic Cast Iron Roll (SGP Roll)

-

Duplex High Speed Steel Roll & Ring (HSS ROLL)

-

Tungsten Carbide Rolls

-

Acicular Nodular Cast Iron Roll (SGA Roll)

-

Alloy Indefinite Chilled Cast Iron Rolls(ICDP Rolls)

-

Forged Steel Rolls for Hot Rolling Mills

-

Adamite Steel Roll and Ring

-

En-HiCr cast steel roll/En-HiCr cast iron roll

-

Alloy cast steel roll

-

Graphite steel roll

-

Enhanced ICDP rolls

-

Forged Steel Rolls for Cold Rolling Mills

-

The Forged Roll Production Flowchart

-