Sidebar

- Home

- Production

- Adamite steel roll and ring

- Alloy indefinite chilled roll and ring(ICDP roll)

- Alloy steel roll

- Graphite steel roll

- Nodular cast iron pearlitic roll and ring

- Nodular cast iron acicular roll and ring

- Enhanced (EN) ICDP roll

- EN HiCr roll

- HSS roll and ring

- Tungsten carbide roll ring

- Forged steel roll for hot rolling mill

- Forged steel roll for cold rolling mill

- Forged roll production flowchart

- News

- About Us

- Contact Us

- Download

- CNC Roll Lathe

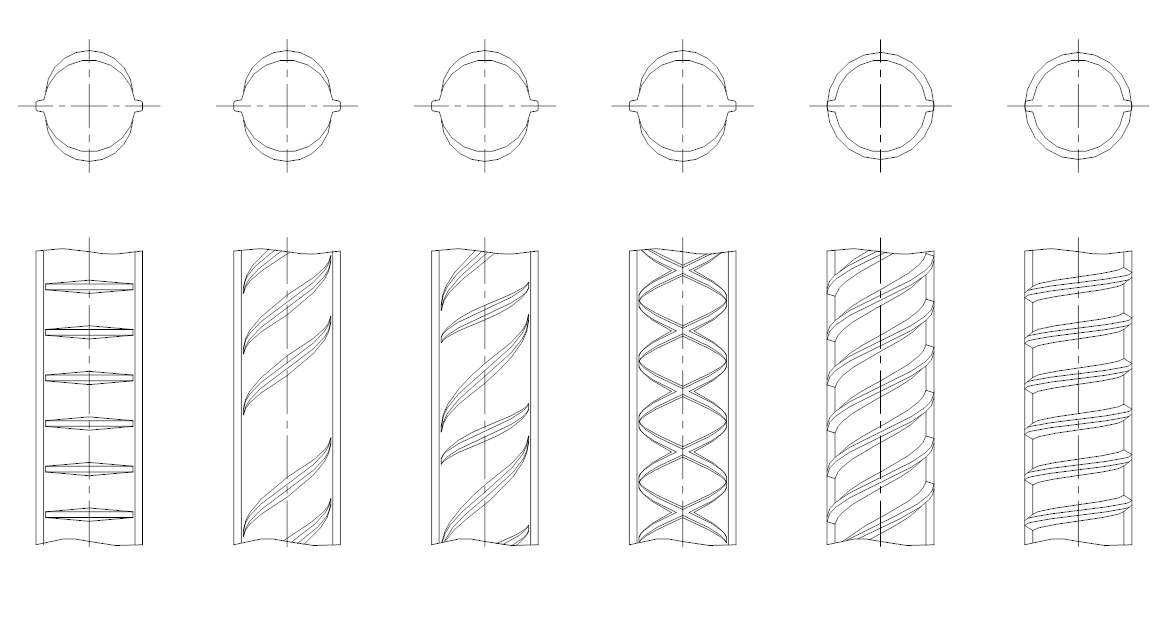

CK8460 CNC Roll Lathe, is suitable for machining ribbed bar transverse rib of high speed steel and high nickel chromium composite cast iron roll.

Requirements as below:

- Machining roll material, ribbed steel bar specifications and materials

- Max surface hardness of HSS rolls HRC=60.

- Max surface hardness of high nickel chromium composite cast iron roll HRC=53.

- Machining meets the requirements of drawing standards and accuracy.

- Roll dimensions: Max/Min×Roll Length=φ600/100×2500mm

- Function

Turning the outer circle and pass profile of rolls on cast iron, high-speed steel rolls, alloy rolls, etc.

CK8470*2500 CNC Heavy duty Roll Turning lathe suitable for roughing and finishing section mill rolls with profiles of the cast iron roll or high speed steel or tungsten carbide roll etc.

The CK8470*2500 CNC heavy duty roll turning lathe are suitable for workpiece up to the following data:

Max. Diameter to be machining : 700mm

Max. center distance:2500mm

Max roll weigh on center:8000Kg

CNC controller: siemens 828D

XK500G CNC notch milling machine installed with Seimens808D (4 axis server motor and 1 spindle VFD), suitable for tungsten carbide roll or high speed steel roll or high-nickel-chromium composited roll, or cast iron roll.

-

CNC roll lathe

-

Production

-

Nodular Pearlitic Cast Iron Roll (SGP Roll)

-

Duplex High Speed Steel Roll & Ring (HSS ROLL)

-

Tungsten Carbide Rolls

-

Acicular Nodular Cast Iron Roll (SGA Roll)

-

Alloy Indefinite Chilled Cast Iron Rolls(ICDP Rolls)

-

Forged Steel Rolls for Hot Rolling Mills

-

Adamite Steel Roll and Ring

-

En-HiCr cast steel roll/En-HiCr cast iron roll

-

Alloy cast steel roll

-

Graphite steel roll

-

Enhanced ICDP rolls

-

Forged Steel Rolls for Cold Rolling Mills

-

The Forged Roll Production Flowchart

-